AMUT WATERPROOFING MEMBRANE EXTRUSION LINES

AMUT membrane extrusion lines, offered regionally through EXTRUDAMERICA, are engineered to produce high-performance waterproofing and barrier membranes that boast unmatched mechanical strength, dimensional stability, and weather resistance, instilling confidence in their quality.

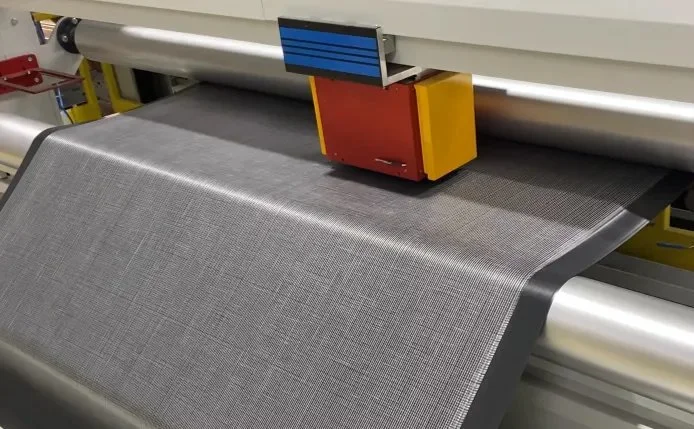

These extrusion systems, with their support for mono- and multi-layer configurations and full compatibility with a wide range of reinforced substrates such as fiberglass matting, scrim, polypropylene nets, or polyester mesh, offer a reassuring level of flexibility for various industries and compliance with UEATC civil application standards.

ADVANCED MANUFACTURING CAPABILITIES

Width Range: Lines configured for 2300 mm and 3600 mm net widths

Throughput: Up to 4500 kg/h, depending on formulation and layer count

Reinforcement Options: Fiberglass, scrim, PP/PET nets, or mats embedded mid-layer

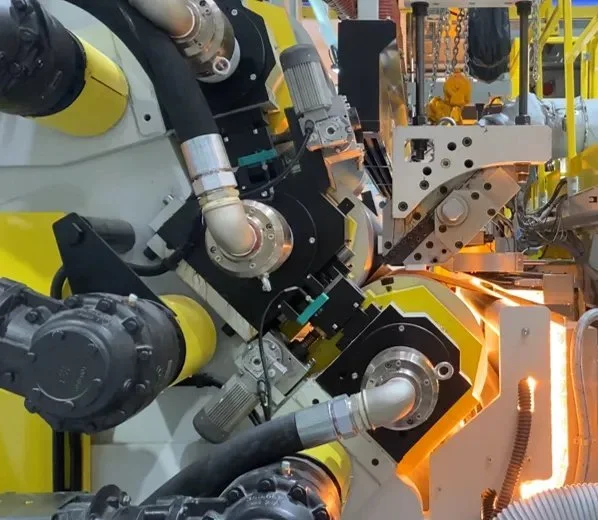

Calendaring Units: Available in single and tandem calendar configurations for thickness control and embossing

Winding System: Handles “jumbo” rolls over 7 tons, ready for palletizing and storage

TNT Fleece Lamination: Optional non-woven fleece backing directly laminated in-line for structural membranes

Film Types: Compatible with TPO, PVC, F/PVC, and TPE formulations

These extrusion systems are configured with advanced controls for line speed, tension, thickness distribution, and online embossing. These controls allow customers to tailor membranes for demanding civil, industrial, or commercial applications, ensuring precise and consistent product quality.

APPLICATIONS OF AMUT-EXTRUDED MEMBRANES

AMUT membrane lines cater to a diverse range of industry needs. Common applications include:

➤ Construction and Civil Engineering

Flat roofing systems (low- and mid-slope)

Below-grade waterproofing for basements and garages

Structural slabs and decking isolation

Parking decks and bridge underlays

Modular building waterproof layers

➤ Heavy-Duty Waterproofing

Tunnels: Single- or double-layer lining to prevent water ingress and freeze-thaw deterioration

Foundations: Pre-applied or post-applied waterproofing to concrete foundations

Water reservoirs: UV-resistant membranes with fleece-backed reinforcement for flexible containment

Landfills: Reinforced geomembranes used as impermeable barriers for leachate containment

Canals and channels: Durable membranes to retain water and protect from seepage

Retaining walls: Secondary barrier membranes as part of building envelope solutions

➤ Industrial Soundproofing & Vibration Damping

Laminated barrier membranes for acoustic control in HVAC and wall structures

TPO or PVC-based sheets for machinery enclosures and ducting

Flooring underlays with reinforced layers for commercial acoustic suppression

➤ Aerospace & Specialty Applications

Low-weight, high-reflectivity membranes for thermal insulation or cavity sealing

Engineered sheets for aircraft bay linings and containment panels

Fire-retardant or modified PVC membranes for transport infrastructure

➤ Automotive & Footwear

Sheet-fed materials for thermoforming wheel well liners or underbody shields

Vinyl or composite-backed membranes for floor mats and noise insulation

TPO membranes for waterproof footwear components or boot linings

WHY CHOOSE AMUT FOR MEMBRANE EXTRUSION

EU-Grade Compliance: All membranes comply with UEATC and EN standards

Integrated Systems: All extrusion lines come with complete winding, cutting, and stacking options

Local Expertise and Support: Full personalized and trusted assistance from EXTRUDAMERICA LLC

VIDEO SHOWCASE OF AMUT MEMBRANE EXTRUSION Lines

WATERPROOFING MEMBRANE TECHNOLOGY

Multi-layer membranes with scrim or fiberglass reinforcement for dimensional stability under extreme conditions. Surface embossing, fleece bonding, and aesthetic finish options available. Designed for buildings, tunnels, and reservoirs with low maintenance and high reflectivity.

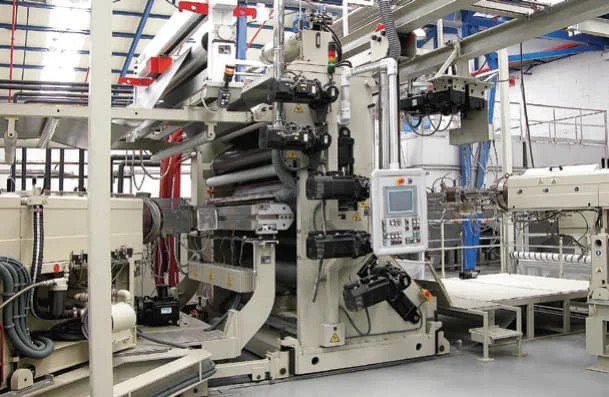

S/PVC WATERPROOFING MEMBRANES TANDEM EXTRUSION LINE

Flexible membrane line with tandem extrusion setup. Produces geomembranes and waterproofing sheets for civil engineering applications. Optimized for large width sheets, tight thickness tolerance, and durable weather-resistant performance.

WATERPROOFING THERMOPLASTIC MEMBRANES EXTRUSION LINE

Three-layer configuration with scrim or fiberglass inner reinforcement. Thermoplastic membranes built to meet EU standards. Excellent weather durability, light-colored surfaces for solar reflectivity, low maintenance, and reduced material weight.